Sorcóir aer dlúth aeroibrithe sraith CQ2

Cur síos ar an Táirge

Is féidir leis na sorcóirí seo sá a ghiniúint trí ghás a aistriú go cuas loine an tsorcóra, agus an sá a tharchur chuig páirteanna meicniúla eile trí shlat loine an tsorcóra. Úsáidtear go forleathan iad i línte táirgeachta uathoibríocha, déantúsaíocht innealra, trealamh pacáistithe, trealamh priontála agus réimsí eile.

Tá dea-chobhsaíocht agus in-atrialltacht ag sorcóirí sraith CQ2, agus is féidir leo rialú seasamh cruinn agus freagra tapa gníomhaíochta a bhaint amach. Is féidir leo luas agus fórsa difriúil a bhaint amach tríd an mbrú agus an sreabhadh sa sorcóir a choigeartú.

Sonraíocht Theicniúil

| Méid Tórraimh(mm) | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Mód Aisteoireachta | Aisteoireachta Dúbailte | |||||||||

| Meáin Oibre | Aer Glanta | |||||||||

| Brú Oibre | 0.1-0.9Mpa(kaf/ceintiméadar cearnach) | |||||||||

| Brú Cruthúnas | 1.35Mpa(kaf/ceintiméadar cearnach) | |||||||||

| Teocht Oibre | -5~70 ℃ | |||||||||

| Mód Maolánaithe | Cushion Rubair | |||||||||

| Méid an Phoirt | M5 | 1/8 | 1/4 | 3/8 | ||||||

| Ábhar Coirp | Cóimhiotal Alúmanam | |||||||||

| Mód | 16 | 20 | 25 | 32 | 40 | 50 | 63 | 80 | 100 |

| Athraigh Braiteoir | D-A93 | ||||||||

| Méid Tórraimh(mm) | Stróc Caighdeánach(mm) | Stróc Uasta(mm) | Stróc Incheadaithe(mm) | |||||||||

| 12 | 5 | 10 | 15 | 20 | 25 | 30 |

|

|

|

| 50 | 60 |

| 16 | 5 | 10 | 15 | 20 | 25 | 30 |

|

|

|

| 50 | 60 |

| 20 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 90 |

| 25 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 80 | 90 |

| 32 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 40 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 50 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 63 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 80 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

| 100 | 5 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 130 | 150 |

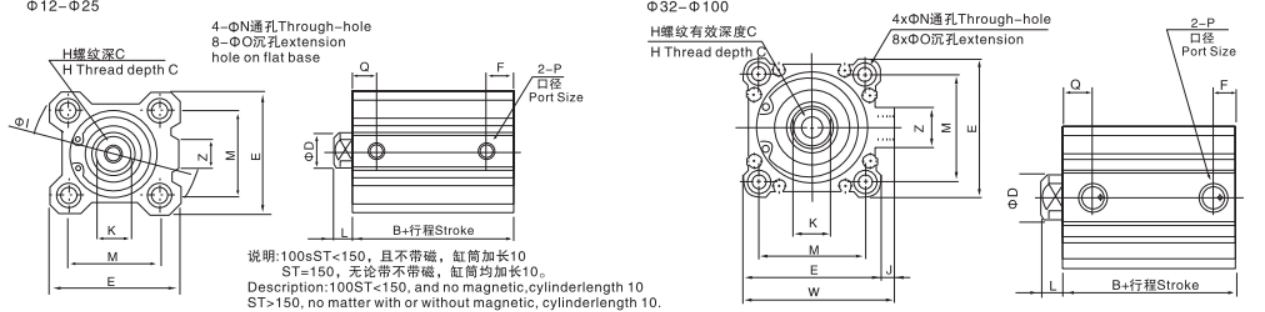

| Méid Tórraimh(mm) | B | ΦD | E | F | H | C | I | J | K | L | M | ΦN | ΦO | P | Q | W | Z | |

| Cineál maighnéad | Cineál caighdeánach | |||||||||||||||||

| 12 | 27 | 17 | 6 | 25 | 5 | M3X0.5 | 6 | 32 | - | 5 | 3.5 | 15.5 | 3.5 | 6.5 doimhneacht 3.5 | M5X0.8 | 7.5 | - | - |

| 16 | 28.5 | 18.5 | 8 | 29 | 5.5 | M4X0.7 | 8 | 38 | - | 6 | 3.5 | 20 | 3.5 | 6.5 doimhneacht 3.5 | M5X0.8 | 8 | - | 10 |

| 20 | 29.5 | 19.5 | 10 | 36 | 5.5 | M5X0.8 | 10 | 47 | - | 8 | 4.5 | 25.5 | 5.5 | 9doimhneacht7 | M5X0.8 | 9 | - | 10 |

| 25 | 32.5 | 22.5 | 12 | 40 | 5.5 | M6X1.0 | 12 | 52 | - | 10 | 5 | 28 | 5.5 | 9doimhneacht7 | M5X0.8 | 11 | - | 10 |

| 32 | 33 | 23 | 16 | 45 | 9.5 | M8X1.25 | 13 | - | 4.5 | 14 | 7 | 34 | 5.5 | 9doimhneacht7 | G1/8 | 10.5 | 49.5 | 14 |

| 40 | 39.5 | 29.5 | 16 | 52 | 8 | M8X1.25 | 13 | - | 5 | 14 | 7 | 40 | 5.5 | 9doimhneacht7 | G1/8 | 11 | 57 | 15 |

| 50 | 40.5 | 30.5 | 20 | 64 | 10.5 | M10X1.5 | 15 | - | 7 | 17 | 8 | 50 | 6.6 | 11doimhneacht3 | G1/4 | 10.5 | 71 | 19 |

| 63 | 46 | 36 | 20 | 77 | 10.5 | M10X1.5 | 15 | - | 7 | 17 | 8 | 60 | 9 | 14doimhneacht10.5 | G1/4 | 15 | 84 | 19 |

| 80 | 53.5 | 43.5 | 25 | 98 | 12.5 | M16X2.0 | 20 | - | 6 | 22 | 10 | 77 | 11 | 17.5doimhneacht13.5 | G3/8 | 13 | 104 | 25 |

| 100 | 63 | 53 | 30 | 117 | 13 | M20X2.5 | 27 | - | 6.5 | 27 | 12 | 94 | 11 | 17.5doimhneacht13.5 | G3/8 | 17 | 123.5 | 25 |

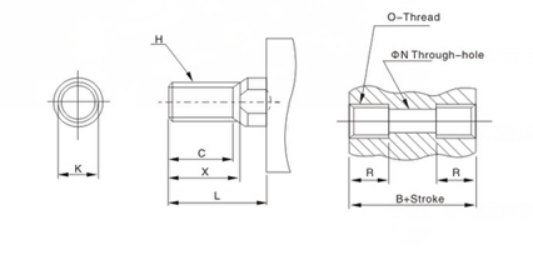

| Méid Tórraimh(mm) | C | X | H | L | O1 | R |

| 12 | 9 | 10.5 | M5X0.8 | 14 | M4X0.7 | 7 |

| 16 | 10 | 12 | M6X1.0 | 15.5 | M7X0.7 | 7 |

| 20 | 13 | 14 | M8X1.25 | 18.5 | M6X1.0 | 10 |

| 25 | 15 | 17.5 | M10X1.25 | 22.5 | M6X1.0 | 10 |

| 32 | 20.5 | 23.5 | M14X1.5 | 28.5 | M6X1.0 | 10 |

| 40 | 20.5 | 23.5 | M14X1.5 | 28.5 | M6X1.0 | 10 |

| 50 | 26 | 28.5 | M18X1.5 | 33.8 | M8X1.25 | 14 |

| 63 | 26 | 28.5 | M18X1.5 | 33.5 | M10X1.5 | 18 |

| 80 | 32.5 | 35.5 | M22X1.5 | 43.5 | M12X1.75 | 22 |

| 1002 | 32.5 | 35.5 | M26X1.5 | 43.5 | M12X1.75 | 22 |